Top 10 Questions About Tires

What is the proper inflation for my tires?

Wheel Works recommends using the tire pressure that the vehicle manufacturer recommends. This information located on the Tire Information Placard is normally located on the inside driver's door jamb. We suggest you do not deviate from this tire pressure. Pressure requirements may change when plus sizing tires. You may use the tool above to view the manufacturer recommended inflations for standard sized tires on your vehicle.

This information is compiled from third party sources and is for your informational purposes only. This information is offered on an "as is" basis. Wheel Works does not warrant or make any representations regarding the use of or the results of the use of this information. Consult your vehicles owner's manual for further information. This disclaimer is in addition to the wheelworks.net terms and conditions.

What is the mileage warranty on my O.E. (original equipment) tires?

O.E. tires are designed to the vehicle manufacturer's specifications and do not offer a mileage warranty. However, your tires are warranted for workmanship and material defects.

What is meant by speed rating?

The speed rating of a tire indicates the speed category (or range of speeds) at which the tire can carry a load under specified service conditions. The speed rating system used today was developed in Europe in response to the need to control the safe performance of tires at standardized speeds. A letter from A to Z symbolizes a tire's certified speed rating, ranging from 5 km/h (3mph) to above 300 km/h (186 mph). This rating system, listed below, describes the top speed for which a tire is certified. It does not indicate the total performance capability of a tire.

When this speed rating system was originally developed, the Unlimited V category of over 210 km/h (130 mph) was the top speed rating a tire could achieve.

| SPEED RATING | ||

|---|---|---|

| Speed Symbol | Speed (km/h) | Speed (mph) |

| A1 | 5 | 3 |

| A2 | 10 | 6 |

| A3 | 15 | 9 |

| A4 | 20 | 12 |

| A5 | 25 | 16 |

| A6 | 30 | 19 |

| A8 | 40 | 25 |

| B | 50 | 31 |

| C | 60 | 37 |

| D | 65 | 40 |

| E | 70 | 43 |

| F | 80 | 50 |

| G | 90 | 56 |

| J | 100 | 62 |

| K | 110 | 68 |

| L | 120 | 75 |

| M | 130 | 81 |

| N | 140 | 87 |

| P | 150 | 94 |

| Q | 160 | 100 |

| R | 170 | 106 |

| S | 180 | 112 |

| T | 190 | 118 |

| U | 200 | 124 |

| H | 210 | 130 |

| V | 240 | 149 |

| W | 270 | 168 |

| Y | 300 | 186 |

As manufacturers made more tires that did not fit this category, it was necessary to better regulate performance at standardized speeds to ensure safety. The Limited V category of 250 km/h (149 mph) was then created, and the Z speed rating was added as the top speed rating that a tire could achieve. W and Y limited speed symbols have been added as higher speed categories.

Always consult the manufacturer for the maximum speed of Unlimited Z tires. Speed rating is identified as a part of the tire's sizing or service description.

In the latest attempt to standardize tire designations, all ratings except Unlimited ZR incorporate the speed symbol and load index as the tire's service description. For example:

| 205/60R15 91V | |

|---|---|

| 205 = Section Width in Millimeters | |

| 60 = Aspect Ratio | |

| R = Radial Construction | |

| 15 = Rim Diameter in Inches | |

| 91 = Load Index | (Service Description) |

| V = Speed Symbol | |

When "ZR" appears in the size designation with the service description, the maximum speed is as indicated by the service description:

| EXAMPLES | |

|---|---|

| Tire Designation | Maximum Speed |

| P275/40ZR17 93W | 270 km/h (168 mph) |

| P275/40ZR17 93Y | 300 km/h (186 mph) |

For tires having a maximum speed capability above 240 km/h (149 mph), a "ZR" may appear in the size designation. For tires having a maximum speed capability above 300 km/h (186 mph), a "ZR" must appear in the size designation. Consult the tire manufacturer for maximum speed when there is no service description.

What does UTQG mean?

Uniform Tire Quality Grading

UTQG is intended to provide simple, comparative data for your use in making an informed buying decision. However, the ratings are based upon test results achieved under very specific conditions. As a result, misinterpreting the comparative data as it relates specifically to your particular driving habits, conditions, etc., is a possibility. UTQG designates the comparative performance levels of a tire based upon government-specified tests. Tire manufacturers and brand name owners are required to grade regular and all-season tires in three categories: Treadwear, Traction, and Temperature.

Dot Quality Grades

All passenger car tires must conform to Federal Safety Requirements in addition to these grades.

Treadwear

The treadwear grade is a comparative grade assigned by the manufacturer based on the wear rate of a tire when tested under controlled conditions on a course that meets government-specified requirements. For example, a tire graded 150 would wear one and a half (1 1/2) times as well as a tire graded 100 under the controlled test conditions. The relative performance of tires depends upon the actual conditions of their use and may depart significantly from the norm due to variations in driving habits, service practices and differences in road characteristics.

Traction AA, A, B, C

The traction grade is based on wet skid tests of a tire on government-specified concrete and asphalt surfaces. The traction grade is based on a straight-ahead wet braking traction test and does not include a cornering traction test. The comparative tire grade letters, AA, A, B, and C (AA being the highest and C being the lowest) represent the tire's ability to stop the vehicle on wet pavement under the controlled test conditions. Ice and snow traction capabilities are not tested.

Warning:

The temperature grade is established for a tire that is properly inflated and not overloaded. Excessive speed, under inflation, or excessive loading, either separately or in combination, can cause heat buildup and possible tire failure.

Example #1:

A tire with the ratings of TREADWEAR 80, TRACTION B, TEMPERATURE C, is interpreted by the manufacturer as having:

- TREADWEAR grade less than that of a tire graded 100.

- TRACTION capability greater than tires of C grade, but not as good as tires of AA or A grade.

- TEMPERATURE performance on the laboratory high-speed test greater than required by the government standards, but less than tires graded B or A.

Example #2:

A tire with same brand name and same construction type with ratings of TREADWEAR 160, TRACTION A, TEMPERATURE B, compares to the tire in example #1 as follows:

- TREADWEAR is graded two times better than the tire in example #1.

- Wet TRACTION and TEMPERATURE are better than the tire in example #1.

Important Note

Keep in mind that comparing the performance of various tires is too complex to be based exclusively on UTQG grades.

- UTQG grades are not government grades. They are manufacturer grades that are not based on head-to-head interbrand testing. Test data is not typically submitted to the National Highway Traffic Safety Administration.

- Treadwear grades are not a guarantee for a given mileage warranty, or an indicator of overall tire quality. Treadwear grades are assigned by the manufacturer for comparison purposes within the same brand names and construction types only.

- UTQG grades are not safety ratings. Overall tire quality and safety are not graded. Tire selection based on any one, two, or even three UTQG ratings may not satisfy your needs.

- One brand name of tires cannot be considered superior or inferior to another brand name of tires based solely on UTQG grades.

- UTQG grades are not required for snow tires, light truck tires and maximum traction tires.

- UTQG is used but not required in Canada.

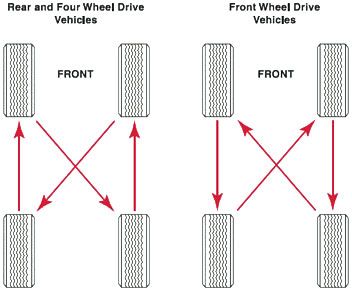

What is the proper way to rotate tires?

4-tire Rotation

Did you know that front tires wear out almost twice as fast as rear tires on a front-wheel drive vehicle? Also keep in mind that uneven tire wear may be due to mechanical problems like a misaligned suspension. On average, tires should be rotated every 5,000 miles and more frequently for high performance tires.

Wheel Balancing

Do you feel steering wheel vibration between 50 and 70 miles per hour? Out of balance wheels can create poor handling and a significant reduction in fuel mileage. We recommend wheel balancing with every tire rotation.

What do I need to know about tire repair?

Driving an improperly repaired tire is dangerous. An improper repair can be unreliable or permit further damage to the tire. The tire may suddenly fail, causing serious personal injury or death. A complete inspection and repair of your tire in accordance with Rubber Manufacturers Association (RMA) procedures should be conducted by a qualified tire service professional.

A proper tire repair includes the following:

- The tire is demounted from the wheel for a complete inspection, inside and out. Some damage to the tire may only be evident on the interior of the tire.

- The puncture injury is ¼ inch (6 mm) or less and must be within the tread area. This helps ensure the long-term tire and repair durability.

- A patch is applied to the interior of the tire and the puncture hole is filled with a suitable plug/stem filler. This helps ensure that the interior of the tire is adequately sealed to prevent inflation pressure loss and prevents contamination of the steel belts and other plies from the elements (such as water) in the outside world.

Additional notes about tire repairs:

- Not all punctured or damaged tires can be properly repaired; consequently, some tires must be replaced. NEVER repair a tire with any of the following conditions:

- Wear to the tire's built-in treadwear indicators or to 2/32 inch (1.6 mm) remaining tread depth in any area of the tread.

- With a puncture larger than ¼ inch (6 mm).

- With a puncture or other damage outside the repairable tread area.

- With a pre-existing, improper repair.

- Any tire repair done without removing the tire from the wheel is improper. The tire must be demounted from the wheel and the interior inspected for damage that may not be evident on the exterior of the tire.

- Using only a plug/stem, or using only a patch, is not a safe or proper repair. A patch must be applied to the interior of the tire and the puncture hole must be filled with a suitable plug/stem filler to prevent inflation pressure loss and contamination of the steel belts and other plies.

- NEVER substitute a tube for a proper repair or to remedy an improper repair.

- Tubes, like tires, should only be repaired by a qualified tire service professional.

- Some vehicle manufacturers do not recommend using repaired tires. Consult your vehicle owner's manual or contact the vehicle manufacturer before operating a repaired tire on your vehicle.

- The tire's speed rating is void if the tire is repaired, retreaded, damaged, abused, or otherwise altered from its original condition. It should be treated as a non-speed rated tire.

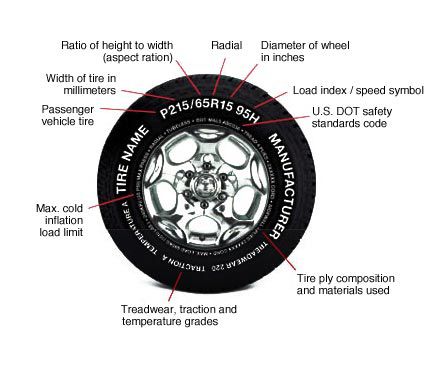

How do I read the sidewall of my tires?

What you should know about your tires

There is valuable information about your tires printed right on the sidewall.

What is the repairable area of a tire?

Non-RFT (Non Run Flat Tires)

We only repair tires in accordance with the RMA (Rubber Manufacturers Association) recommended procedures. Some punctures cannot be seen with the naked eye and other measures are taken to find such punctures (soapy water and tire water tubs).

RFT (Run Flat Tires)

No tire, regardless of its design or quality, is indestructible. RFT tires can be ultimately rendered unusable due to a puncture or other road hazard as well as from improper run-flat or low pressure operation. Some punctures may be repaired under certain circumstances, with restrictions and subject to prescribed procedures.

When driven flat or with low pressure, factors affecting reparability include vehicle speed, load, handling and maneuvering; the amount of inflation pressure lost; and ambient temperature. In any situation, the extent and location of direct damage from a puncturing object or other road hazard are also critical factors.

RFT tires are not repairable in any of the following situations:

- If the tire is described as, "Do Not Repair" on the sidewall.

- If the tire was operated with inflation pressure less than 15 psi (100 kPa).

- Abrasion or other damage is present on the exterior tread, sidewall or bead areas.

- Abrasion, wrinkling, or separation is present on the tire interior.

- Any condition or damage is present that disqualifies repair of a conventional tire.

Run-Flat Certified Retailers will fully inspect your tire, inside and out, to determine if the tire can be repaired. Tire damage is not always visible from the outside and the tire must be removed from the wheel for a complete inspection.

Note: Some vehicle manufacturers recommend not using repaired tires. Such recommendations apply to RFT tires. Use of RFT tires deemed non-repairable may result in damage to the vehicle, injury, or death. Consult your vehicle owner's manual or contact the vehicle manufacturer before operating a repaired tire on your vehicle.

Why did my tires wear so quickly?

Premature tire wear may be caused by many factors other than tire rotation. Some examples are as follows: improper inflation, driving conditions, misaligned vehicles, worn vehicle parts and many other reasons.

Without physically inspecting the tires it is difficult to make a determination as to why your tires wore prematurely. Please visit our location and have one of our trained professionals inspect your tires free of charge.

What is the rolling resistance of my tires?

Rolling resistance has traditionally been measured through SAE (Society of Automotive Engineers) test procedure J1269. It measures the force required to roll a tire against a dynamometer at a fixed speed of 50 mph. Within Wheel Works, we have over 1,300 passenger and light truck products in the Bridgestone line alone and, conceivably, each one could have a different rolling resistance. The tread compound is a major factor, but construction, size, and even tread pattern can have an influence. At least 3 tires must be run in each configuration to get a good average. At approximately 1 hour per rolling resistance test, this amounts to 3,900 hours or over 6 months just to run the Bridgestone brand.

This explains why these values are estimated. We have some data, however it frequently does not line up with those sizes or patterns requested. Therefore, estimation is required.

These estimates are made by independent organizations. Wheel Works does not test for rolling resistance.